Powerful lithium-air batteries may soon “take batteries to the next level,” reveals study

03/24/2019 / By Edsel Cook

Chicago-based researchers have come up with a new way to improve the performance and safety of lithium-ion batteries. They are going to remove the ionic part of the battery and replace it with air.

These so-called lithium-air batteries have not yet left the experimental phase of development. However, they are already being touted as the next logical step for lithium-based energy storage technology.

A lithium-air battery is expected to store the same amount of energy as 10 conventional counterparts of the same size. The advanced design also weighs much less than a lithium-ion equivalent.

Furthermore, researchers believe they can raise the energy efficiency of lithium-air batteries even further. These increases can be accomplished by incorporating newly designed catalysts into the battery.

A catalyst improves the rate of reactions in a chemical process. The storage of energy in a battery counts as one such process. So does the release of the stored energy.

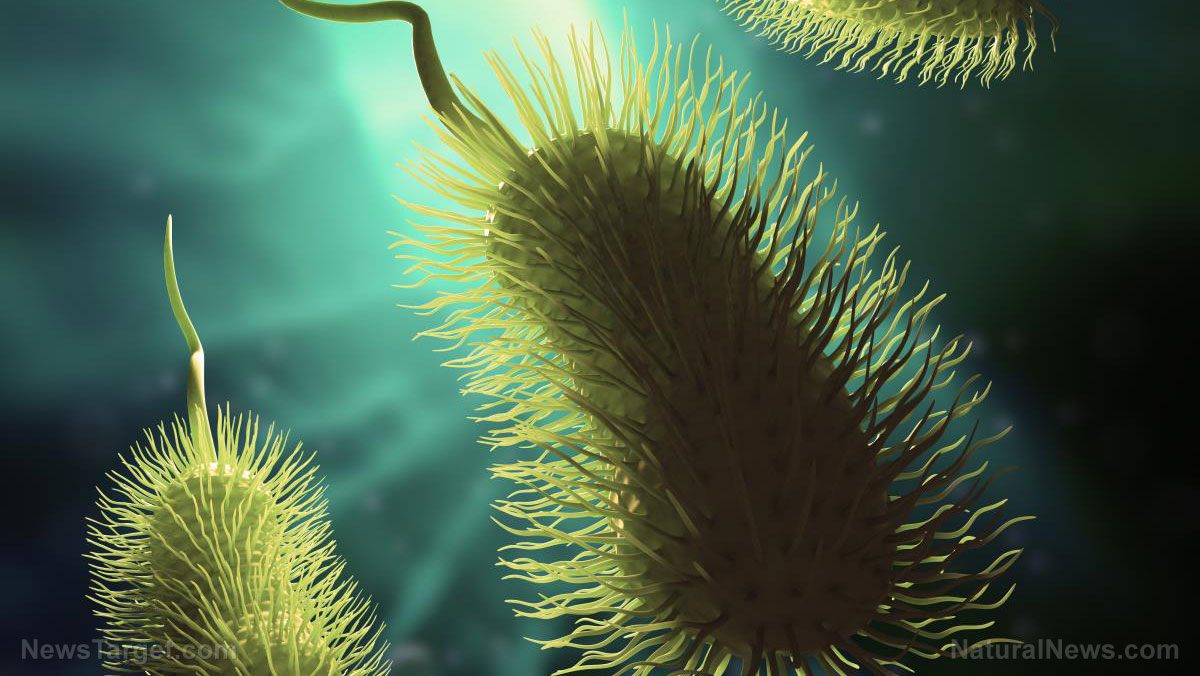

The new catalysts are made from two-dimensional materials. A sheet of these materials is only as thick as a single atom. Ounce for ounce, these ultra-thin materials have much greater surface areas than conventional materials. (Related: Researchers develop a new type of nano computer chip that uses transistors made from AIR.)

Two-dimensional catalysts can supercharge lithium-air batteries even further

University of Illinois in Chicago (UIC) researcher Amin Salehi-Khojin speaks about the need for new batteries that can store even greater amounts of energy. Such high-energy density devices are required to power the increasing numbers of power-hungry phones, laptops, and electric vehicles.

Salehi-Khojin and his fellow researchers made a number of two-dimensional materials that can supercharge various chemical reactions. Some of their new nano-thin materials can be added to lithium-air batteries.

In the scientific paper he published in Advanced Materials, Salehi-Khojin said that the incorporation of two-dimensional catalysts increased the energy storage capacity of a lithium-air battery by 1,000 percent when compared to a similar unit that uses conventional catalysts.

“Currently, electric vehicles average about 100 miles per charge, but with the incorporation of 2D catalysts into lithium-air batteries, we could provide closer to 400 to 500 miles per charge, which would be a real game-changer,” he remarked.

The future of energy storage is two-dimensional (materials)

Salehi-Khojin’s team used two-dimensional transitional metal dichalcogenides (TMDCs) to create 15 varieties of catalysts. TMDCs are very good electronic conductors that can transfer electrons at a very fast rate.

The transferred electrons can be used to power chemical reactions between two different types of materials. In batteries, these electrons will be stored for later discharge.

In their experiment, the UIC researchers tested the ability of each TMDC material to serve as a catalyst for a lithium-air battery. While they did not have such a battery on hand, they did have an electrochemical system that made for a good substitute.

The two-dimensional form of TDMCs gave them higher electronic properties and a larger surface area with which they could trigger electrochemical reactions. Furthermore, the new catalysts were able to maintain the stability of their shape.

When compared to older catalytic materials, the TDMC catalysts achieved much higher rates of chemical reactions. They were also much more versatile, being able to accelerate both the charging process and its opposite discharging process.

“This would be what is known as bi-functionality of the catalyst,” explained Salehi-Khojin.

Last but not least, the TDMC catalysts were highly compatible with the electrolyte material. The researchers concluded that the combination of lithium-air batteries and catalysts made from two-dimensional materials can take batteries to a new level of efficiency.

Sources include:

Tagged Under: 2D catalyst, 2D materials, batteries, battery technology, breakthrough, Chemistry, cool science, discoveries, electricity, energy, future science, innovation, inventions, lithium-air battery, lithium-ion battery, materials research, physics, power